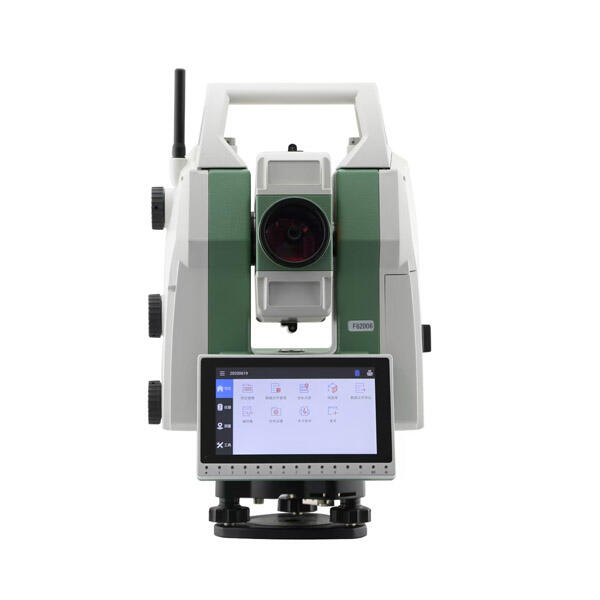

total station robotic

A total station robotic is an advanced surveying instrument that combines electronic distance measurement technology with automated tracking and control capabilities. This sophisticated device integrates multiple components including an electronic theodolite, electronic distance meter, and computerized systems that enable autonomous operation. The instrument can automatically track targets, measure angles and distances with high precision, and store data digitally. Modern total station robotics feature remote control capabilities, allowing surveyors to operate the instrument from a distance using a controller. They incorporate advanced software for real-time data processing, 3D modeling, and stake-out functions. These instruments excel in various applications, from construction layout and topographic surveys to monitoring structural deformation and mapping utilities. The technology employs servo motors for automated movement, enabling precise positioning and tracking of prisms or other targets. Many models include features like automatic target recognition, reflectorless measurement capability, and wireless communication protocols for seamless data transfer. The integration of GPS technology in some models further enhances their positioning capabilities, making them invaluable tools for modern surveying operations.