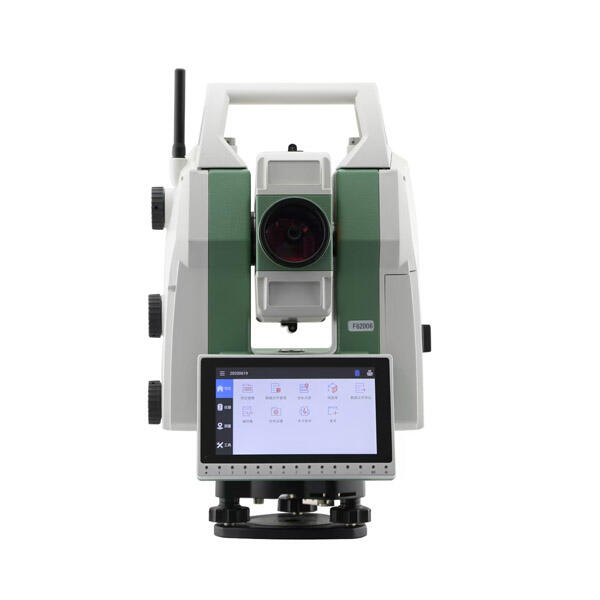

robotic total station

A robotic total station represents a groundbreaking advancement in surveying and construction technology, combining precision measurement capabilities with automated operation. This sophisticated instrument integrates electronic distance measurement, angle sensing, and robotic automation to provide highly accurate positioning and tracking capabilities. The device operates through a motorized system that automatically tracks a target prism, eliminating the need for manual operation. It features advanced software integration that enables real-time data collection, processing, and transmission, making it an invaluable tool for modern construction and surveying projects. The robotic total station can perform precise measurements of angles, distances, and coordinates, while its built-in computer systems can calculate complex geometrical relationships and store vast amounts of data. Its robotic functionality allows for single-person operation, as the instrument automatically follows a prism mounted on a survey pole, continuously measuring and recording positions. The technology incorporates state-of-the-art servo motors for precise movement control, advanced optical systems for accurate targeting, and sophisticated software for data management and analysis. These features make it particularly useful in applications ranging from construction layout and as-built surveys to monitoring structural deformation and precise positioning tasks.