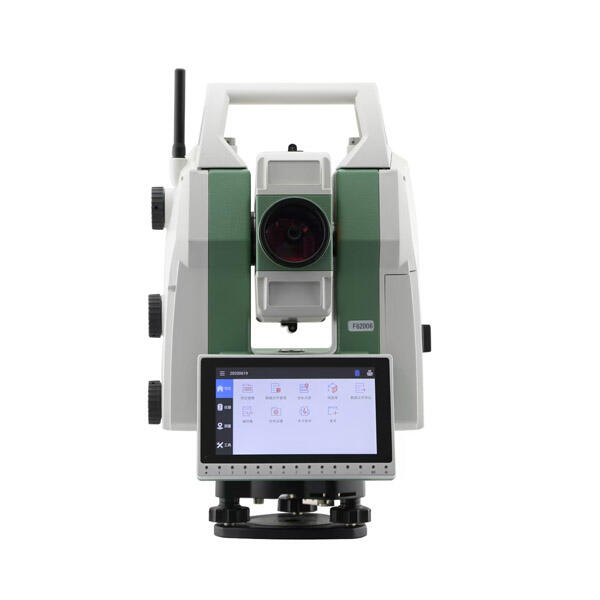

android total station factory

The android total station factory represents a cutting-edge manufacturing facility dedicated to producing advanced surveying instruments that combine traditional total station capabilities with modern Android operating systems. This state-of-the-art facility employs precision engineering and automated assembly lines to create instruments that offer unprecedented accuracy and user-friendly interfaces. The factory implements rigorous quality control measures throughout the production process, ensuring each unit meets international standards for surveying equipment. The facility's production line integrates advanced robotics and human expertise to manufacture total stations that feature built-in Android systems, enabling seamless integration with modern surveying software and apps. The factory's research and development department continuously works on improving the technology, focusing on enhancing measurement accuracy, battery life, and wireless connectivity capabilities. Their production processes incorporate environmental considerations, utilizing energy-efficient manufacturing methods and sustainable materials whenever possible. The factory's output includes various models of Android total stations, ranging from entry-level units for basic surveying tasks to high-end professional models capable of millimeter-precise measurements and advanced data processing. Each unit undergoes extensive testing in simulated field conditions before leaving the facility, ensuring reliability and durability in real-world applications.